All One-Source Partners are Not Created Equal: Understanding the Winning Difference of DFM

The product development chain is made up of multiple links that include various stages of design, engineering, and manufacturing. When selecting a product development partner, companies tend to contract with three separate partners — one for each link in the chain — or engage a one-source partner that handles all three.

Hidden Disadvantages

Both choices can make good sense but can come with hidden disadvantages. The disadvantage of handing off each link in a larger chain to three different partners is that the chain is necessarily broken. While steps can be taken to mitigate this, when each stage of the product development process is not integrated into the larger whole, the risk that problems will occur is far greater.

At first glance, it may appear that a one-source partner automatically eliminates these risks since the chain remains unbroken. But does it? The assumption that the chain will remain intact often turns out to be unfounded. Just because a single company handles design, engineering, and manufacturing doesn’t mean these links are effectively integrated. The challenge here is that most one-source partners approach these stages in a linear fashion. In other words, the product proceeds first through design, then through engineering, and then on to manufacture. This is a sub-optimal approach that is likely to result in a product that fails to fulfill its market potential.

The development of a superior product requires a holistic approach in which design, engineering, and manufacturing are integrated from the very beginning. Only a partner with DFM — Design for Manufacturing — delivers the expertise that ensures each link in the chain is undertaken with the other links in mind. DFM is its own specialty — it’s not simply a matter of assembling cross-functional teams comprised of design, engineering, and manufacturing professionals.

How DFM Talent is Different

Few product design professionals have been adequately trained to think in terms of engineering and manufacturing. Instead, they tend to think in terms of how a product looks, feels, and performs. While they are likely to ask questions like, “Is this design pleasing to the eye? Is it user-friendly? Does it perform as expected?” they do not ask other critical questions related to engineering, supply chain, or manufacturing. These questions include, “What are the chief engineering challenges that the development of this design must overcome? What supply chain challenges might this design potentially pose? What are the design parameters in which this innovation can be cost-effectively manufactured at scale?”

On the other hand, DFM talent is holistically trained to ask each of these questions to optimize the design for scalable manufacture. The ability to bring these critical questions to bear from the very beginning has everything to do with the end product’s success. DFM safeguards against breaks in the product development chain that can easily lead to missed opportunities for innovation, excessive product iterations, extended delays, scope creep, delayed time to market, and lost revenue. Without DFM, the result is often a dazzling design that cannot be cost-effectively manufactured.

Maintaining the Integrity of the Chain

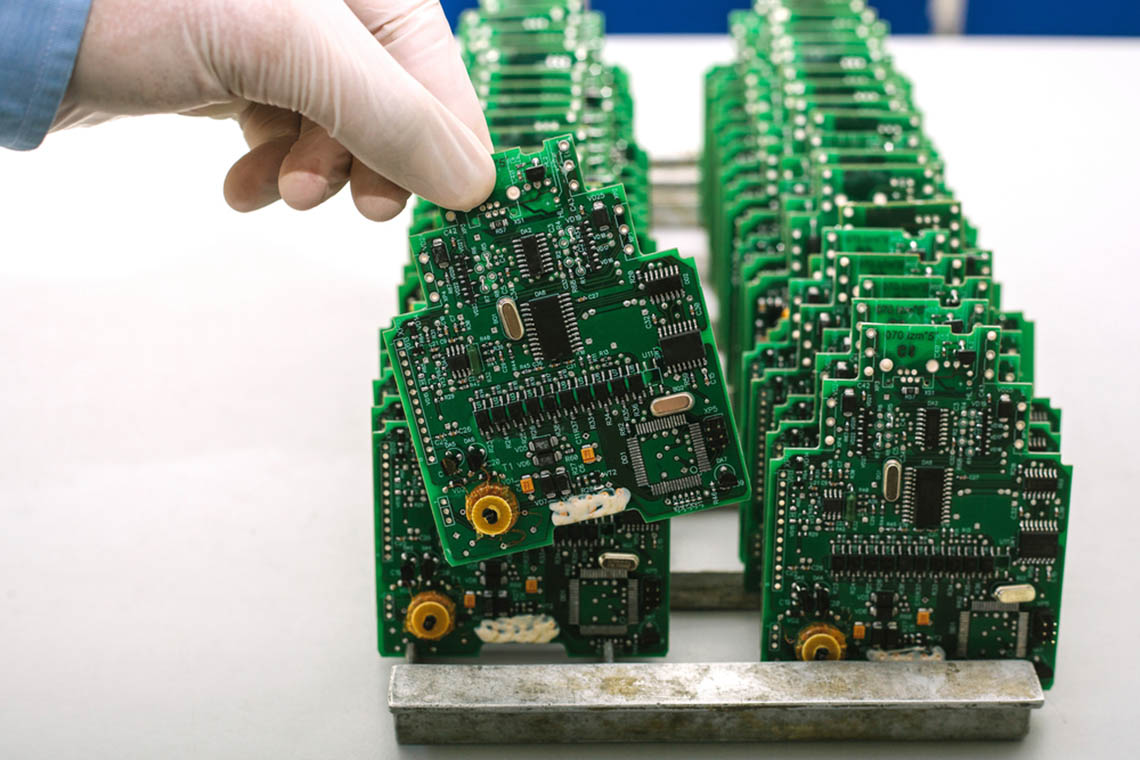

A one-source partner with top DFM talent maintains the integrity of the product development chain from start to finish. It ensures a smooth, seamless process that results in superior products that fulfill their market potential. At Pivot International, we are proud to be one of the few one-source leaders with in-house DFM talent and 320,000 square feet of flexible manufacturing capability for serving clients worldwide. With nearly a half-century of proven DFM expertise that spans fourteen industries, we are the trusted partner behind some of the world’s most prestigious and award-winning innovations.

If you’re looking for a highly collaborative DFM partner with a proven track record of success, contact us today for a no-cost consultation. Together, we’ll transform your product vision into a successful reality that will put your company on your map.