Five Reasons Why Design for Manufacturing (DFM) is Essential to Product Success

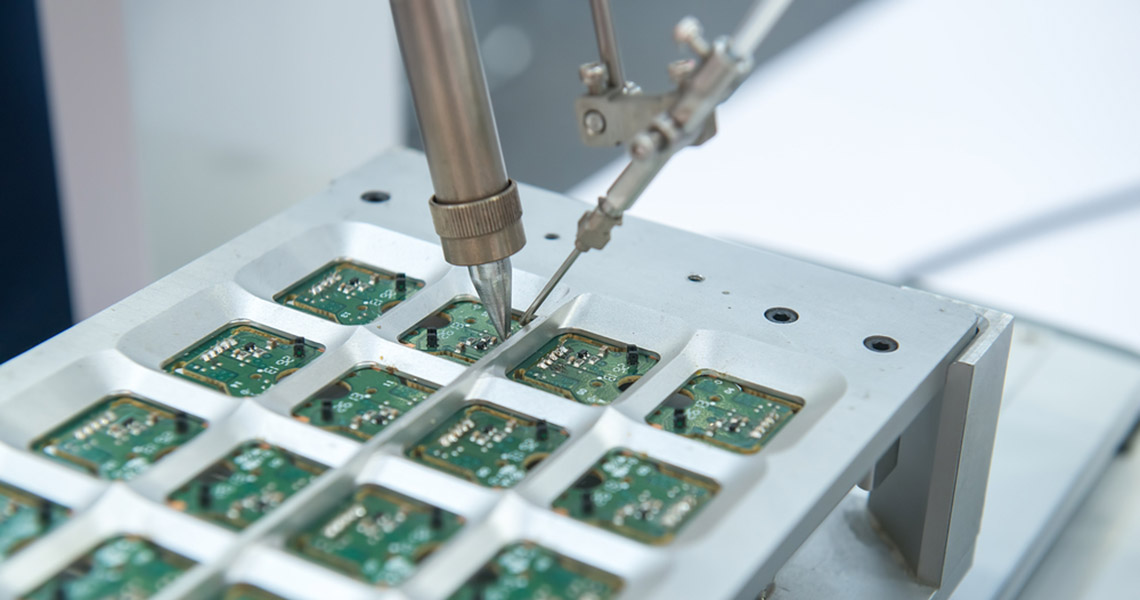

If you’re in the process of developing a new product, it’s critical to choose a partner with Design for Manufacturing (DFM) expertise. DFM ensures that the design process is undertaken with a clear understanding of potential manufacturing limitations and supply chain challenges. By integrating design and manufacturing, DFM delivers a host of competitive advantages.

At Pivot International, DFM is a crucial part of our industry-leading one-source business model. With product development expertise that spans fourteen industries and extensive manufacturing capability that spans three continents, DFM plays an integral role in our client-focused success strategies.

DFM provides significantly greater insight into the product development process and adds additional layers of security. For this reason, it represents a critical capability for ensuring client success. Here’s how DFM benefits your business.

Increased Cost-Effectiveness

The goal of bringing a new product to market begins and ends with cost-considerations. DFM increases cost-effectiveness by looking at design in relation to manufacturing investment, reconciling the two to maximize ROI.

A design may be visionary on paper, but if it can’t be cost-effectively produced to scale, it’s destined for market failure. DFM helps defend against sunk costs because it builds in safeguards early in the product development process. The later a design and manufacturing incompatibility is recognized, the more difficult and expensive it is to correct. DFM all but guarantees this problem won’t occur.

Avoidance of Scope Creep

DFM also provides security against scope creep. When design is decoupled from manufacturing considerations and production metrics, a project will almost always be more complex, lengthy, and expensive than anticipated.

Scope creep can demoralize teams, rapidly deplete resources, and bring product development to a halt. DFM brings a detailed understanding of how multiple moving parts fit together to reveal the bigger picture. This picture can then be translated into a comprehensive project plan that leaves no stone unturned and little room for surprises.

Optimized Processes

DFM is more than just an “add on” to design. It optimizes the design process itself by helping designers to clarify their focus. It also optimizes processes and drives efficiencies across all areas of product development. DFM ensures that design, engineering, and manufacturing processes are never created in a silo. This means that processes become much more seamless, and drag is eliminated, expediting time-to-market.

Enhanced Innovation

DFM fuels innovation by forcing designers to devise novel solutions for working around limitations that are intrinsic to manufacturing. This may seem counter-intuitive since many people think that innovation is about defying limitations. While this is true, innovation is also about reconceiving limitations by viewing them through a new lens. DFM provides this lens, helping designers to view the design process from a broader perspective.

Apple founder, Steve Jobs, was famous for saying, “Design isn’t just what it looks like, it’s how it works,” and he might as well have been talking about DFM. DFM ensures that design doesn’t devolve into an “aesthetic indulgence,” unmoored from functional and cost-considerations.

Improved Supply Chain Security

Thanks to pandemic-driven disruption, company leaders are becoming more vigilant about the relationship between manufacturing and supply chain security. DFM is inherently related to supply chain. (It makes no sense to optimize a design for manufacture if supply chain challenges prevent the product from being made.) For this reason, DFM is at its most powerful when delivered by a partner with advanced supply chain expertise and alternative sourcing solutions.

Is your company seeking to bring a new product to market?

Our teams at Pivot deliver nearly a half-century of product development experience and DFM expertise that’s behind multiple award-winning innovations. Our one-source model ensures a seamless product development process that cuts costs, prevents scope creep, enhances innovation, and safeguards sourcing to expedite your time-to-market. Contact us today for a no-obligation consultation. We’ll help you make a successful product launch a reality.